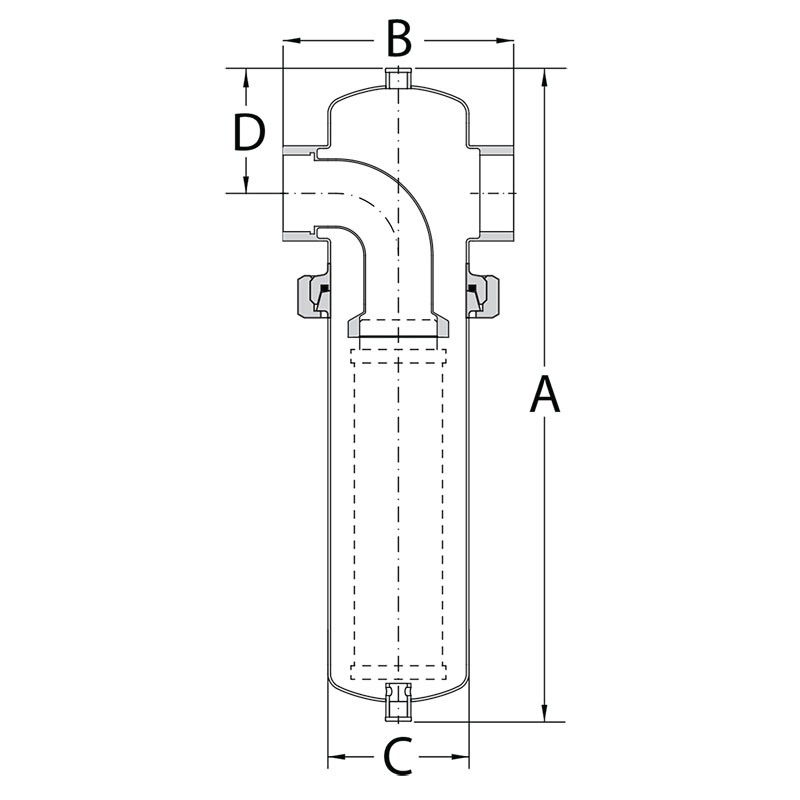

Nano P1 Series Stainless Steel Industrial Filters

flow capacity: 8 - 1500 scfmThe nano P1 range of industrial stainless steel filters are fabricated from polished 304 or 316 stainless steel for critical compressed air and gas applications in the high tech manufacturing, food processing and beverage industries.

The nano range of industrial stainless steel filters encompasses ten models with connections from 1/4” to 3” and rated flows from 50 to 1150 scfm.

Specifically designed to provide efficient and effective contaminant removal in sterile or caustic environments, these filters are ideally suited for process applications such as food and beverage facilities with washdown requirements.

The unique interchangeable borosilicate microfiber filter elements incorporate stainless steel support media and a positive double o-ring click-lock seal to ensure optimal filtration integrity.

• install with air flow from inside to outside for coalescing & from outside to inside for dry dust filtration.

Activated Carbon filters must always be installed immediately downstream of a M01 coalescing filter.

They will not remove carbon monoxide (CO) or carbon dioxide (CO2) and are not suitable for breathing

air applications. The life of the element decreases as the inlet temperature increases. They are not

recommended for temperatures above 77°F. As a maximum, activated carbon elements should be replaced

every 1000 hours or 6 months, whichever is shorter.

Model(s): PF 0050 M1-N, PF 0050 M01-N, PF 0050 AC-N, PF 0065 M1-N, PF 0065 M01-N, PF 0065 AC-N, PF 0085 M1-N, PF 0085 M01-N, PF 0085 AC-N, PF 0120 M1-N, PF 0120 M01-N, PF 0120 AC-N, PF 0170 M1-N, PF 0170 M01-N, PF 0170 AC-N, PF 0295 M1-N, PF 0295 M01-N, PF 0295 M01-N, PF 0295 AC-N, PF 0460 M1-N, PF 0460 M01-N, PF 0460 AC-N, PF 0680 M1-N, PF 0680 M01-N, PF 0680 AC-N, PF 0850 M1-N, PF 0850 M01-N, PF 0850 AC-N, PF 1150 M1-N, PF 1150 M01-N, PF 1150 AC-N

(1) at 100 psig. For all other pressures, refer to the pressure correction factor table

(2) +/- 0.118"

➤Click Here for Correction Factors

(3) per ISO 8573-1:2010

(1) at 100 psig. For all other pressures, refer to the pressure correction factor table

(2) +/- 0.118"

➤Click Here for Correction Factors

(3) per ISO 8573-1:2010

Click for Larger View

Click for Larger View Click for Warranty Policy Summary

Click for Warranty Policy Summary